Industrial Low NOx Burners

Faber provides industrial low NOx burners of unparalleled flexibility and performance, gas, oil, dual fuel or tri-fuel fired with heat input capacities 0.5 – 300 MMBTU/hr. Most designs larger than 10 MMBTU/hr allow up to three fuels to be fired independently or simultaneously. Offering rugged and user-friendly designs for nearly every application from ultra low NOx to alternative fuels.

FOREFRONT Gas Fired Low NOx Burners

Nozzle mix burner with integral combustion air blower and butterfly air damper

- 0.5 – 10 MMBTU/hr heat input

- Natural gas, Propane or Ethane fuels fired

- Simple, Rugged, & Reliable

- Quick Deliveries

- For Air Heaters, Dryers, Incinerators, Industrial Furnaces, Kilns, Immersion Tube Firing, Ovens, Steam Generators, Thermal Fluid Heaters and Thermal Oxiders

LxE – Modular Design Gas Fired Low NOx Burners

Ideal for emission level compliance driven retrofits utilizing the existing fan, controls and pipe trains

- 13 – 62 MMBTU/hr heat input

- Natural gas fired

- LE model with guaranteed NOx emissions as low as 50 ppm without FGR

- L2E model with guaranteed NOx emissions as low as 30 ppm without FGR

- L3E model with guaranteed NOx emissions as low as 15 ppm with FGR

- Self contained, flexible, cost effective high performance gas burners

- For process heaters, kilns, furnaces, dryers, and oxidizers

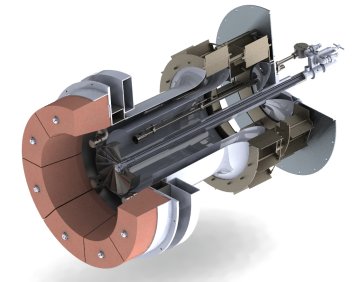

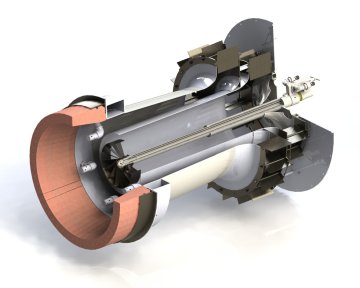

VPSSS – Gas, Oil or Alternative Fuel Fired Low NOx Burners

- 10 – 300 MMBTU/hr heat input

- Natural gas, oil or nearly any liquid or gaseous fuel fired

- One, two or three fuels can be fired; either one at a time or simultaneously

- VPSSS model with guaranteed NOx emissions as low as 50 ppm without FGR, sub 30 ppm with FGR

- VPSSS-SGB model with guaranteed NOx emissions as low as 30 ppm without FGR

- VPSSS-SGB model with guaranteed NOx emissions as low as 15 ppm with FGR

- Supplied as part of a new windbox (WB) package burner system or retrofitted to an existing windbox.

- Unique features minimize start-up, commissioning, ownership and operating costs

- For watertube boilers, HTHW Generators, process heaters, kilns, furnaces, dryers, and oxidizers

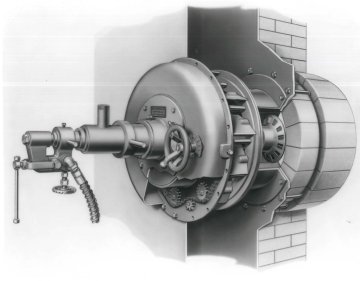

Faber Legacy Register Burners