Industrial Low NOx Register Burners

Faber provides industrial low NOx register burners of unparalleled flexibility and performance. Most designs allow up to three fuels to be fired independently or simultaneously. Offering rugged and user-friendly designs for nearly every application from ultra low NOx to alternative fuels. The Faber register burner design stands alone by allowing the combustion air degree of swirl to not only be set at the time of commissioning, but also to provide on-line flame shaping for effortless combustion performance optimization. Faber register assemblies can be supplied as part of a new windbox (WB) package burner system or retrofitted to an existing windbox.

VPSSS-SGB & VPSSS Register Burners

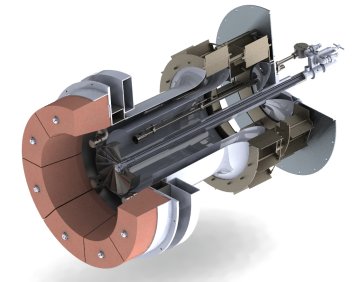

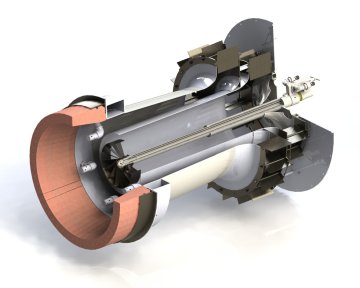

Faber VPSSS series burners are high performance low emission multi-fuel venturi profile register burners. They offer the end user exceptional value for applications requiring low NOx, CO, VOC and particulate emissions with or without flue gas recirculation (FGR). The VPSSS series burners are optimized to burn natural gas or #2 oil, but can be configured to burn nearly any liquid or gaseous fuel. One, two or three fuels can be fired; either one at a time or simultaneously. Every unit is sized and configured for the project specific environmental, thermal, fuel and physical constraint conditions. Burner heat input capacities range from 10 – 300 MMBTU/hr. The VPSSS series burner’s unique features minimize start-up, commissioning, ownership and operating costs. For these reasons they have become a favorite of the rental boiler and thermal fluid heater industries.

Features common to all VPSSS Series Register Burners

- Guaranteed NOx, CO, VOC and particulate emission rates

- Rugged, dependable and durable proven design

- Extremely reliable spark ignited gas pilot

- Unique gas spud design results in extremely quiet and stable operation

- Unique manually adjustable register turning vanes allow instant online flame shaping when required for flame to furnace fit and fuel change flame quality optimization. These vanes also minimize startup and commissioning time.

- Easily retrofitted to existing windboxes with CFD designed air baffle package

- Low draft losses reduce fan energy consumption

- 10:1 turndown on gas / 8:1 turndown on oil reduce burner on/off cycling

- Up to 500ºF combustion air temperature

- 4 – 10 PSIG gas supply pressure and 70 – 120 PSIG oil supply pressure

- Responsive customer service team for future engineered upgrades, parts and service

VPSSS-SGB Register Burners

VPSSS-SGB Register Burner, the low NOx solution without FGR, the ultra Low NOx Solution with FGR

NOx emissions as low as 12 ppm, with low levels of CO, and trace amounts of VOC and particulate emissions with FGR on Natural Gas Fuel

NOx emissions as low as 12 ppm, with low levels of CO, and trace amounts of VOC and particulate emissions with FGR on Natural Gas Fuel- NOx emissions as low as 25 ppm, 100 ppm CO and trace amounts of VOC and particulate emissions without FGR on Natural Gas Fuel

- High performance oil burner

- VPSSS-SGB Low NOx Register Burner Bulletin

VPSSS Register Burners

VPSSS Register Burner, the low emission, low excess air solution with or without FGR

NOx emissions as low as 18 ppm, with low levels of CO, and trace amounts of VOC and particulate emissions with FGR on Natural Gas Fuel

NOx emissions as low as 18 ppm, with low levels of CO, and trace amounts of VOC and particulate emissions with FGR on Natural Gas Fuel- NOx emissions as low as 50 ppm, 30 ppm CO and trace amounts of VOC and particulate emissions without FGR on Natural Gas Fuel

- Low excess air operation (as low as 2% Oxygen in the flue gas) reduces fuel costs

- High performance oil burner

- VPSSS Low NOx Register Burner Bulletin