Center-Fired Burner Case Study

Enabling 100:1 Turndown

Recent production changes at a major tire manufacturer required maximum boiler operating flexibility and a unique combustion solution as a result. Understanding that boiler cycling is not only highly inefficient, detrimental to equipment longevity, and disruptive to production, an extremely high turndown ratio was required for the plant’s 100 MMBtu/hr natural-gas boiler.

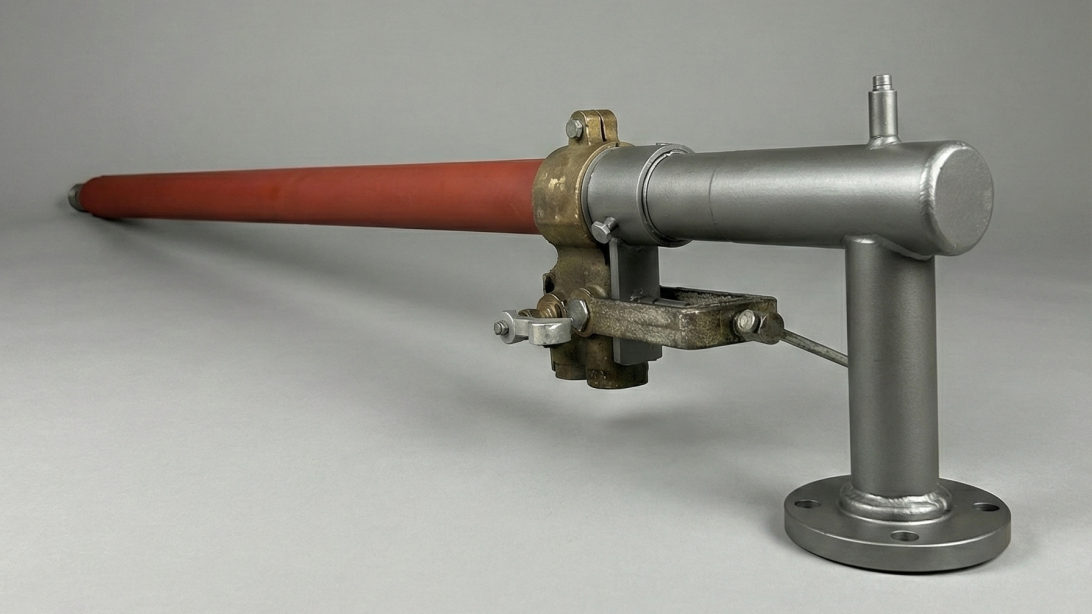

In order to safely extend the existing burner’s thermal turndown from 10:1 down to 100:1 required an auxiliary center fired gas gun lance burner capable of seamless stability between 1 and 10 MMBtu/hr.

Faber Was Asked For A Solution

Faber didn’t just supply a part; we engineered a strategic retrofit. Analyzing the competitor’s burner front, our team designed a custom center fired burner specifically to replace the existing fuel-oil gun. By engineering the burner to match the competitor’s exact mounting dimensions, we created a “drop-in” solution.

Once Faber’s submittal drawings were approved, Faber’s manufacturing team fabricated and shipped the custom center fired burner in just a few weeks to meet the customer’s timeline. Upon receipt of the Faber supplied equipment it was quickly installed, with no need for modifications, and successfully commissioned.

Surprised? You Shouldn’t Be!

This project is a good example of the Faber Advantage. We combine deep technical expertise with the agility to deliver custom combustion solutions when time is of the essence. If you are experiencing problems or unique challenges with your burner equipment and want to work with responsive professionals, please give us a call.

1000 East Bald Eagle Street

Lock Haven, PA 17745-3215

Phone: 570-748-4009

Fax: 570-748-4324

E-mail: sales@faberburner.com

Faber Burner Company manufactures industrial and commercial burners for controlling, igniting, and firing liquid and gaseous fuels in boilers and furnaces.

Add your email address below.

© 2026 Faber Burner Company | Privacy Policy