by: Joseph Colannino, Ph.D.

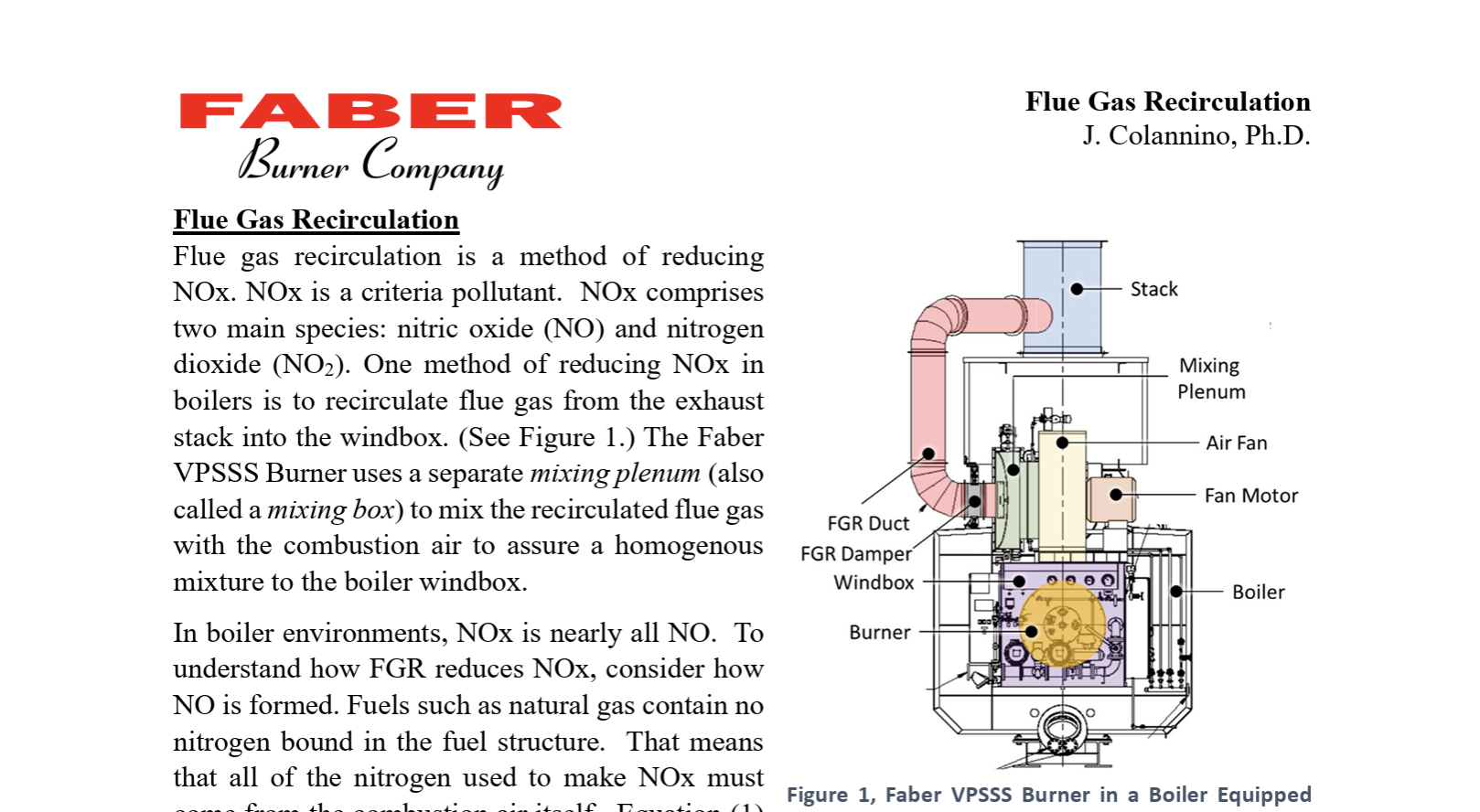

Flue gas recirculation is a method of reducing NOx. NOx is a criteria pollutant. NOx comprises two main species: nitric oxide (NO) and nitrogen dioxide (NO2). One method of reducing NOx in boilers is to recirculate flue gas from the exhaust stack into the windbox. (See Figure 1.) The Faber VPSSS Burner uses a separate mixing plenum (also called a mixing box) to mix the recirculated flue gas with the combustion air to assure a homogenous mixture to the boiler windbox. In boiler environments, NOx is nearly all NO. To understand how FGR reduces NOx, consider how NO is formed. Fuels such as natural gas contain no nitrogen bound in the fuel structure. That means that all of the nitrogen used to make NOx must come from the combustion air itself. Equation (1) is known as the shorter Zeldovich mechanism. It shows the essential features of nitric oxide formation in combustion systems.

This is a preview. Press “download” to see the rest of the document

Joseph Colannino, P.E., is CEO of Colannino Consultants, LLC, where he consults on combustion and pollution control. He also teaches industrial courses on process optimization, improving research and development R&D, and the art of technical presentation and communication. With more than 30 years of experience in the power, chemical, and petrochemical industries, he specializes in leading process teams to develop profitable innovations. He has more than 100 patents pending and granted, and many of his innovations are still in revenue-producing service. He has authored or co-authored several books on combustion, pollution control, and experimental design. Colannino received his BS in chemical engineering from California Polytechnic Univ. at Pomona and MS in knowledge management from the Univ. of Oklahoma. He is a registered professional chemical engineer in California.

1000 East Bald Eagle Street

Lock Haven, PA 17745-3215

Phone: 570-748-4009

Fax: 570-748-4324

E-mail: sales@faberburner.com

Faber Burner Company manufactures industrial and commercial burners for controlling, igniting, and firing liquid and gaseous fuels in boilers and furnaces.

Add your email address below.

© 2026 Faber Burner Company | Privacy Policy